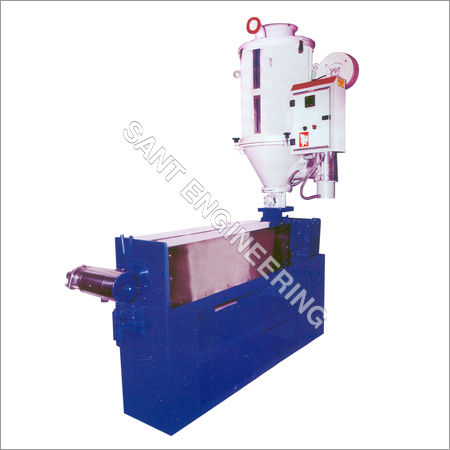

Single Screw Extruder

Product Details:

Product Description

Supported by dedicated team of professionals, we have been able to manufacture and export Single Screw Extruder. Precisely engineered by us at par with the international industrial standards and norms using certified quality metals, these extruders are immensely used for mixing, smelting and extruding of varied materials. Available in different models for high speed extrusion lines, our Single Screw Extruder can be customized by us as per application specific requirements.

Key Features:

- Embedded with single & multiphase water tanks

- Excellent durability

- Rust proof

Cable extrusion lines for:

- switching and control cables

- power cables

- xlpe lt/ht cables

- auto cables

- rubber cables

- instrumentation and special cables

- simmersable cables

Scope of supply:

- single screw extruder ranging 25 mm to 150 mm screw diameter

- cross heads self centre,die centre

- tripple head for ht xlpe cables

- capstan units

- caterpillars phneumatic

- pay off take phneumatic/column pintle type/a type as per requirement up to 3200 mm drum

- dancer/auto coilers/semi auto matic coilers

- air wiper/straightner

Sant Extruder is the product of 42 years of research and development. We offer 25mm to 150mm size extruders for various materials such as PVC, PE, HDPE Sioplas, XLPE Nylon etc

Special Features (Screw / Barrel):

- Screw and Barrel are the most important elements of an extruder. These components have been the subject of much research and development which has resoulted in the implementation of grooved barrels perfectly adopted to the multi threaded screw.

- The screw made of special nitralloy steel nitrided Polished and bored throughout for oil / water cooling.

- The barrel is also made from nitralloy steel nitrided with mirror polish and honed. Air cooling system on barrel and water cooling at feedering zone also given by us

- Bimetallic material also available on request.

| Model | Max Screw RPM | Drive KW | Max Torque of Screw da/Nm | No of Cooling Zones | Heating Power KW | Indicative Output Kgs/Hr | |

| PVC | PE | ||||||

| SEI 30-26D | 120 | 5 | 32 | 3 | 6 | 30 | 18 |

| SEI 40-26D | 120 | 7.5 | 50 | 3 | 6 | 36 | 25 |

| SEI 50-26D | 120 | 15 | 60 | 3 | 12 | 80 | 30 |

| SEI 65-26D | 120 | 25 | 280 | 4 | 18 | 160 | 100 |

| SEI 80-26D | 100 | 40 | 650 | 5 | 24 | 280 | 180 |

| SEI 90-26D | 100 | 45 | 670 | 6 | 25 | 300 | 190 |

| SEI 100-26D | 80 | 75 | 1100 | 6 | 32 | 400 | 280 |

| SEI 120-26D | 80 | 110 | 1580 | 6 | 36 | 600 | 400 |

| SEI 150-26D | 70 | 225 | 2650 | 6 | 46 | 750 | 500 |